Flexible couplings are mechanisms that connect equipment to shafts so that they can transfer torque/transmit power. In addition to torque transmission, they maintain constant velocity while sending mechanical power from one shaft to another, permit axial movement of one shaft while limiting thrust on the other, and compensate for misalignment while limiting power loss and stress. Flexible couplings contrast with rigid couplings (rigid shaft couplings), which connect shafts with a linear alignment. Read More…

Our shaft couplings are the best around! Not only do we provide you with exceptional levels of customer service but we also provide you with manufacturing and a repair service that you can count on. We are also capable of providing you with special designs. That’s right! Our design team will work closely with you in order to ensure that you are getting the product that will fit your specific...

At Coupling Corporation of America, we devote ourselves to engineering shaft couplings that deliver exceptional precision, durability, and performance for complex motion control and power transmission applications. We design each coupling to accommodate the unique torque, misalignment, vibration, and speed demands of our customers’ equipment, ensuring smooth, efficient operation even under...

Ruland’s carefully made shaft collars, rigid shaft couplings & zero backlash motion control flexible shaft couplings, including beam, Oldham & bellows couplings, are available in both inch & full-metric dimensions. Our line has expanded to include metric shaft collars, metric rigid couplings & step bore rigid couplings. For 70 years, we have supplied custom-made products to meet special needs.

Founded in Buffalo, NY in 1946, Power Drives, Inc. (PDI) designs and manufactures custom-engineered hose and tube assemblies for original equipment manufacturers (OEM), and engineered systems for locomotives and other mobile equipment. PDI also distributes a wide range of hydraulic, pneumatic and electromechanical components for fluid conveyance, motion control and power transmission applications ...

More Shaft Coupling Manufacturers

Applications

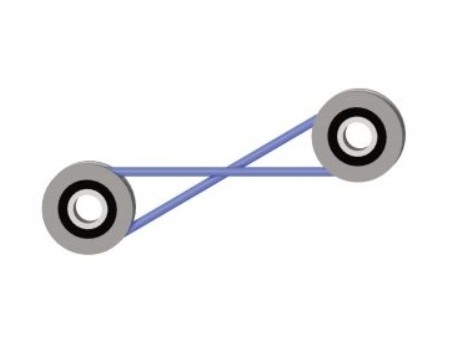

Manufacturers and industrial engineers rely on flexible shaft couplings to connect rotating shafts and efficiently transfer torque in a wide range of rotary equipment and power transmission systems. These mechanical couplings are essential components in applications involving driveshafts, line shafts, conveyor systems, gearboxes, and wheels. Flexible shaft couplings serve not only to transmit rotary motion, but also to isolate propeller pulses, dampen driveline vibrations, minimize resonance, and reduce gear chatter and noise—resulting in smoother and more reliable operation of precision machinery.

Common use cases for flexible shaft couplings span many sectors: they are integral in marine propulsion systems for boats, hydraulic pump assemblies, wind turbines, tube shafts, automotive drivetrains, paper-making equipment, printing presses, compressors, roll formers, and industrial blowers. Their ability to manage misalignment, absorb shocks, and extend the lifespan of connected equipment makes them indispensable in both heavy-duty and high-precision settings.

Industries that heavily depend on flexible shaft couplings for critical machinery and rotating equipment include aerospace, automotive, construction, metal processing, mining, mineral processing, oil and gas, power generation, water treatment, quarrying, cement manufacturing, and renewable energy installations. The versatility and reliability of these couplings ensure continued demand in both legacy and emerging technology sectors.

History

The history of flexible couplings is a testament to the ongoing evolution of mechanical engineering and the drive to enhance rotary motion systems. The earliest recorded use of flexible couplings can be traced back to ancient Greece around 300 BC, where rudimentary designs began to appear, followed by innovations in China around 25 AD.

The 1500s marked a turning point when Italian mathematician Jerome Cardan developed what is now known as the Cardan joint—a pivotal invention featuring a cross, two yokes, and four bearings. This universal joint concept was refined in 1650 by Robert Hooke, who implemented the Hooke joint (Cardan shaft) into clock drives, allowing for more reliable and flexible rotation in timekeeping mechanisms.

The 19th century saw further breakthroughs: in 1821, Irish engineer John Oldham introduced the Oldham coupler to solve misalignment issues in paddle steamers—a design still widely used in modern machinery. In 1886, F.M. Roots advanced the field by modifying rigid couplings to create more flexible ones, laying the groundwork for today’s diaphragm and disc couplings that prevent shaft failure under load.

The industrial revolution and the boom of the automotive sector in the early 20th century accelerated the adoption of flexible couplings. The 1920s witnessed rapid proliferation of coupling types, especially metallic disc couplings, in North America. However, early designs were limited to low-speed, low-torque, and low-misalignment uses.

Engineers between 1930 and 1945 introduced many of the flexible coupling types still in use today—including jaw couplings, disc couplings, gear couplings, chain couplings, slider block couplings, and grid couplings. The post-war period, particularly the 1940s and 1950s, saw a leap in coupling technology, with improved designs that handled greater misalignment, higher speeds, and increased torque—meeting the demands of new rotary machinery and high-performance industrial applications.

In the modern era, flexible shaft couplings have become more sophisticated thanks to advances in materials science, computer-aided design (CAD), and precision CNC manufacturing. Manufacturers now offer a vast array of coupling materials, geometries, and custom solutions to meet the rigorous demands of automation, robotics, renewable energy, and smart manufacturing systems.

Design

Production Processes

The design and manufacturing processes for flexible shaft couplings are critical to achieving optimal performance, durability, and compatibility with diverse machinery. State-of-the-art production techniques include electroforming, chemical deposition, mechanical forming, roll-forming, extrusion, and advanced welding methods.

Electroforming: Electroforming involves the deposition of metal layers onto a mandrel using an electrolytic solution, allowing for highly precise, thin-walled, and intricate coupling geometries. This method is ideal for miniature couplings used in instrumentation and medical devices where tight tolerances are required.

Chemical Deposition: Chemical deposition, or electrodeposition, is similar to electroforming but often used for creating high-strength, corrosion-resistant layers on coupling surfaces, enhancing durability in harsh environments such as marine or chemical processing applications.

Roll-forming: A continuous shaping process, roll-forming uses contoured rollers to form metal strips into precise coupling profiles. This technique is efficient for producing high volumes of uniform, cost-effective couplings for automotive, conveyor, and industrial equipment.

Extrusion: In extrusion, metal or plastic stock is forced through a custom-shaped die, producing coupling components with consistent cross-sections. This is commonly employed for aluminum and polymer couplings, contributing to lightweight and high-performance designs.

Welding: Welding processes are used to join rings or washers, both internally and externally, to maximize coupling strength. Advanced welding ensures structural integrity and high torque capacity, especially in stainless steel and heavy-duty industrial couplings.

Materials

The selection of materials for flexible shaft couplings directly impacts their performance characteristics, longevity, and suitability for specific operating environments. The most common materials include:

- Aluminum: Lightweight and cost-effective, aluminum couplings are favored for applications demanding low inertia and moderate strength, such as in robotics, light-duty automation, and precision instruments.

- Stainless Steel: Known for exceptional strength, corrosion resistance, and the ability to withstand high torque, stainless steel couplings are widely used in marine, chemical, food processing, and heavy industrial environments.

- Engineering Plastics: Advanced thermoplastics and composite materials provide vibration damping, electrical isolation, and chemical resistance, making them ideal for sensitive electronics and laboratory equipment.

- Bronze and Alloy Steels: Used for specialized applications requiring high wear resistance and load-bearing capacity, such as mining, oil and gas, and heavy-duty conveyors.

When selecting a flexible shaft coupling material, consider the application’s torque, speed, environmental exposure, need for corrosion resistance, weight restrictions, and cost constraints. Manufacturers often provide detailed material specifications to guide buyers in choosing the right coupling for their operating conditions.

Types of Flexible Shaft Couplings

Flexible shaft couplings can be classified by their construction, mechanism of flexibility, and intended use. Understanding the different types helps engineers and procurement specialists select the ideal coupling for their specific needs:

Mechanical Flexible Couplings

Mechanical flexible couplings use interlocking parts that slide, roll, or pivot against each other to transmit torque while accommodating misalignment and vibration. Despite requiring periodic lubrication and regular inspection, these couplings are valued for their high torsional rigidity, long service life, and suitability for applications with significant angular misalignment.

- Jaw Couplings (Spider Couplings): Featuring two metal hubs and a resilient elastomeric insert (spider), jaw couplings are renowned for vibration reduction and resistance to contaminants such as moisture, sand, grease, and oil. These couplings are maintenance-friendly as they do not require lubrication, but are best suited for applications with minimal misalignment.

- Oldham Couplings: Oldham couplings are compact, three-disc assemblies that allow for greater lateral misalignment. Their unique tongue-and-groove connection ensures constant velocity and smooth motion transfer in systems where space is limited and alignment is challenging.

- Servo Couplings: Designed for closed-loop servo systems, these couplings deliver high torsional stiffness, low inertia, and zero backlash, making them ideal for CNC machinery, robotics, and high-precision automation.

- Uniflex Couplings: One-piece designs that handle extreme misalignment, high temperatures, and confined spaces, uniflex couplings are used across textiles, robotics, packaging, and agricultural equipment.

- Encoder Couplings: Specialized for linking rotary encoders to drive shafts, encoder couplings ensure accurate signal transmission in position feedback and motion control applications.

- Spacer Couplings: These couplings create a removable space between pump and motor hubs, facilitating easy seal maintenance and minimizing downtime in process industries.

Elastomeric Flexible Couplings

Elastomeric couplings use rubber, plastic, or composite elements to transmit torque between metallic hubs. Their lightweight construction, high vibration dampening, and resilience to misalignment make them popular for a variety of industrial applications.

- Bellows Couplings: Utilized for applications where superior torsional stiffness and non-linear alignment flexibility are necessary, such as in high-speed servo drives, laboratory automation, and precision test equipment.

- Bush Pin Flange Couplings: Featuring rubber bushings to absorb misalignment, vibration, and shock, these couplings are common in pumps, compressors, and heavy-duty drives.

- Tire Couplings: Employing a flexible tire-like element, these couplings allow for substantial angular and parallel misalignment, and are used in conveyor drives and mining equipment.

Metallic Membrane Flexible Couplings

These advanced couplings use thin, flexible metallic membranes to transmit torque and accommodate angular misalignment. While more expensive and typically not suited for offset misalignment, metallic membrane couplings are low-maintenance, require no lubrication, and deliver high torsional stiffness, making them ideal for high-speed turbines, aerospace, and precision drives.

- Fluid Couplings: While technically not flexible couplings, fluid couplings are often paired with flexible couplings to optimize energy transfer and provide soft starting, overload protection, and misalignment tolerance in industrial motor and pump systems.

- Universal Joints (Universal Couplings): These joints allow for both rotation and angular movement, transmitting torque even when shafts are not aligned, and are widely used in automotive drive shafts and heavy-duty machinery.

- Gear Couplings: Designed for applications requiring rotary motion transfer at steep angles, gear couplings are constructed like sprockets and excel in high-torque, high-misalignment scenarios, such as steel mills and rolling equipment.

Custom and Specialty Shaft Couplings

Many manufacturers offer custom shaft coupling solutions to meet highly specific requirements, including miniature couplings for medical devices, magnetic couplings for sealed environments, and high-temperature couplings for furnaces or ovens. Consulting with a manufacturer or coupling specialist is essential for these niche applications.

Misalignment Management

One of the most significant advantages of flexible shaft couplings is their ability to accommodate and correct shaft misalignment, a common challenge in mechanical power transmission systems. Poor alignment can lead to increased wear, vibration, noise, and premature failure of bearings and other components.

Types of Misalignment:

- Parallel Misalignment: Occurs when the axes of the shafts are parallel but not collinear. Typical in conveyor and pump systems where installation tolerances vary.

- Angular Misalignment: Happens when the shafts are at an angle to each other, often resulting from settling, thermal expansion, or improper installation.

- Axial (End-Float) Misalignment: Involves movement of the shafts along their axes, either towards or away from each other, common in high-speed rotating equipment.

- Combined or Skewed Misalignment: A combination of parallel, angular, and axial misalignment, frequently encountered in complex machinery or systems subject to dynamic loads.

Flexible couplings are engineered to absorb these misalignments through their elastic or mechanical elements, protecting connected equipment from excessive stress and extending the overall service life of the system. Selecting the right coupling type based on the specific misalignment scenario is key to maximizing operational efficiency and minimizing downtime.

Axial Displacement Accommodation

Beyond misalignment, flexible shaft couplings also play a vital role in managing axial displacement, or end float. This refers to the movement of shafts along their length, caused by thermal expansion, vibration, or varying loads. Couplings with axial flexibility help absorb these shifts, reducing mechanical stresses and preventing damage to seals, bearings, and adjacent components.

By selecting a coupling designed to accommodate both misalignment and axial displacement, engineers can ensure smoother operation, reduced vibration, and longer equipment life—a critical consideration in high-speed, high-precision, and continuous-duty applications.

Accessories

Enhancing the performance, longevity, and safety of flexible shaft couplings often requires the use of specialized accessories and maintenance tools. Below are some of the most common and valuable accessories to consider:

- Coupling Grease/Lubricant: Specially formulated lubricants reduce friction and wear in mechanical couplings, such as gear and grid couplings. Proper lubrication decreases heat buildup, prevents metal-to-metal contact, and extends service intervals. For elastomeric and dry-running couplings, verify lubricant compatibility.

- Fitting Kits: Comprehensive fitting kits include alignment tools, torque wrenches, shims, fasteners, and installation manuals. Using the correct kit ensures precise installation, optimal torque transmission, and reduces the risk of premature failure.

- Encoder Attachments: Integrating encoders with couplings enables real-time monitoring of shaft speed, direction, and position—crucial for CNC machinery, robotics, and automated assembly lines requiring high-accuracy feedback.

- Keyway Connections: Keyways and keys provide a positive drive connection between the shaft and coupling hub, preventing slippage in high-torque and start-stop applications, such as crushers, mixers, and large pumps.

- Nuts and Bolts: High-strength fasteners are essential for securing coupling components under dynamic loads. Always use manufacturer-recommended grades to prevent loosening due to vibration or torque spikes.

- Repair Kits: Keeping spare inserts, bushings, and fasteners on hand enables swift repairs and minimizes costly downtime in mission-critical machinery.

How do you choose the right coupling accessories?

Consider the operating environment (temperature, moisture, chemicals), torque and speed requirements, alignment tolerances, and the coupling’s construction. Always consult the manufacturer’s guidelines to ensure accessory compatibility and adherence to quality standards.

Where can you source shaft coupling accessories?

Purchase directly from authorized distributors, trusted industrial supply stores, or the original coupling manufacturer. Using genuine, certified accessories helps maintain safety, reliability, and warranty coverage.

Pro Tip: Implement a proactive maintenance plan that includes regular inspection, lubrication, and timely replacement of worn parts. This not only enhances performance but also prolongs the lifespan of your shaft couplings and protects downstream equipment.

Standards

Adhering to international and industry standards is essential for ensuring the safety, reliability, and interoperability of shaft couplings. The use of standardized couplings streamlines maintenance, promotes global compatibility, and provides end-users with confidence in product quality and performance.

Key ISO Standards for Shaft Couplings:

- ISO 14691: Covers terminology, basic dimensions, and testing procedures for flexible and rigid couplings.

- ISO 16021: Specifies requirements for flexible couplings used in general-purpose industrial applications.

- ISO 13041: Relates to couplings for machine tool spindles, ensuring precision and interchangeability.

- ISO 6336: Focuses on gear coupling design and load-carrying capacity.

Compliance with ISO and other relevant standards ensures that couplings from different manufacturers and for various applications are compatible, safe, and reliable. Standardization also simplifies the process of selecting replacements and conducting maintenance, as dimensions and performance ratings are universally recognized.

How do you determine which standards apply to your coupling application?

- Consult the ISO website or your national standards organization for up-to-date information.

- Review technical documentation from coupling manufacturers, who typically specify which standards their products meet.

- Engage with industry experts or mechanical engineers for guidance on complex or specialized projects.

What are the risks of using non-compliant shaft couplings?

Non-standard couplings may be prone to premature wear, failure under load, or lack essential safety features. This increases the risk of accidents, unplanned downtime, and costly repairs—potentially jeopardizing warranty coverage and regulatory compliance.

Benefits of ISO-Compliant Couplings:

- Proven performance and reliability through rigorous testing.

- Interchangeability with standard components and global compatibility.

- Easier maintenance and availability of spare parts.

- Consistent design practices, enhancing safety and reducing engineering time.

In summary, always specify ISO-compliant shaft couplings for new installations or equipment upgrades to maximize operational safety, reliability, and long-term value.

Choosing the Right Manufacturer

Selecting the best flexible shaft coupling for your application starts with choosing the right manufacturer or supplier. Quality, expertise, and support are key differentiators that can impact the long-term reliability and performance of your power transmission systems.

How do you evaluate shaft coupling manufacturers?

- Industry Experience: Look for manufacturers with a proven track record in your specific industry or application, whether it’s automotive, aerospace, industrial automation, or renewable energy.

- Product Range: A broad product line, including standard, custom, and specialty couplings, ensures you can find solutions tailored to your requirements.

- Compliance and Certification: Ensure the manufacturer’s products are ISO-certified and meet relevant national or international standards.

- Technical Support: Top manufacturers offer engineering support, CAD models, rapid prototyping, and application-specific advice for optimal product selection.

- Delivery and Lead Times: Reliable suppliers offer prompt delivery options and flexible logistics to minimize downtime and keep your projects on schedule.

- After-Sales Service: Robust warranty programs, spare parts availability, and ongoing technical assistance are vital for long-term satisfaction.

On this page, you’ll find a curated list of reputable shaft coupling suppliers and manufacturers, each vetted for quality and reliability. Before contacting potential partners, clearly define your technical requirements: torque range, speed, misalignment tolerance, shaft size, operating environment, and any regulatory or industry-specific needs.

What questions should you ask potential coupling suppliers?

- Can you provide references for similar applications or industries?

- What is the expected lead time for standard and custom orders?

- Do you offer engineering consultation or on-site support?

- Are your couplings compatible with my existing equipment or drive systems?

- What testing and quality assurance processes are in place?

- How do you handle urgent repair or replacement requests?

The ideal manufacturer delivers not just a product, but a complete solution—including technical guidance, documentation, and post-sale support. Whether you need high-performance flywheel couplings, torque limiters, automotive driveshafts, or industrial tire couplings, the right supplier will work with you to meet your project goals on time and within budget.

Start your search with confidence: With careful evaluation and clear communication of your needs, you can quickly identify the top three or four manufacturers best suited for your project. Reach out, discuss your requirements, and select the partner who offers the most value and reliability for your unique application.

Frequently Asked Questions

- What are the most common signs of shaft coupling failure?

Excessive vibration, unusual noise, visible wear, misalignment, and increased operating temperatures can all indicate coupling degradation. Early detection and maintenance are key to preventing costly breakdowns. - How can I improve energy efficiency in my power transmission system?

Choose lightweight, precision-balanced couplings, ensure proper alignment, and maintain recommended lubrication schedules. Regular system audits can identify inefficiencies and suggest upgrades. - How do I size a shaft coupling for my application?

Consider torque transmission requirements, shaft diameter, rotational speed (RPM), alignment tolerances, and environmental factors. Use manufacturer-provided charts and selection tools, or consult an applications engineer for assistance. - Where can I find CAD models for shaft couplings?

Many manufacturers offer downloadable CAD files directly from their websites, facilitating design integration and reducing prototyping time. - Can flexible shaft couplings be retrofitted to existing equipment?

Yes, in most cases. Ensure the replacement coupling matches the shaft dimensions, torque specifications, and misalignment needs of your system. Consult the manufacturer for retrofitting guidance and best practices.

Explore More Shaft Coupling Solutions

Browse our directory of trusted shaft coupling manufacturers to compare products, download technical datasheets, and request quotes.

Still have questions? Start your search with targeted queries like:

- “Which shaft couplings are best for high-speed applications?”

- “How do elastomeric couplings compare to metallic membrane couplings?”

- “What maintenance schedule is recommended for gear couplings?”

Use these prompts as you explore our resources or reach out to suppliers for detailed answers tailored to your project.

Investing in the right flexible shaft coupling solution can dramatically improve uptime, reduce maintenance costs, and maximize the efficiency of your mechanical drive systems. Let our resources guide you on your journey to reliable power transmission and mechanical excellence.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services